GRINDING SPINDLES

HIGHLIGHT THE PRODUCT SEARCH

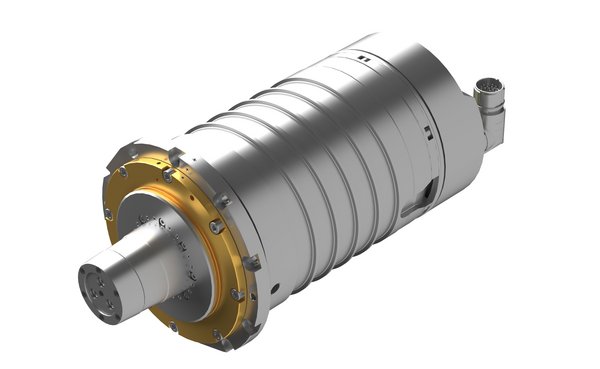

Motor spindles for internal grinding

High-quality internal grinding spindles adapted to the application for best surface qualities.

External grinding

High-quality external grinding spindles adapted to the application for best surface qualities.

- External grinding spindles with one-sided or two-sided tool interface

- Robust, high-precision bearing systems

- Customized, machine-specific solutions according to the machine manufacturer's specifications

- Integrated, automatic balancing systems as an option

Dressing spindles

Dressing and profiling of grinding wheels by powerful motor spindles with robust bearings.

- Highest concentricity and rigidity for precise dressing

- Robust, high-precision bearing system

- Thermal stability

- Asynchronous or synchronous motors for high motor power

- Cylindrical spindle housing or direct mount housing

- Rotary encoder and spark detection as option

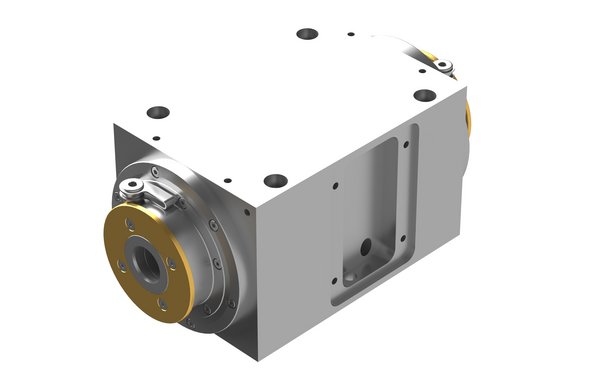

Tool grinding

Tool grinding with compact, high-torque and powerful motor spindles.

- Compact design

- Asynchronous and synchronous motors

- Robust, high-precision bearing system

- Automatic tool clamping system HSK-E50/F63 or manual tool interfaces

Glass processing

Grinding and polishing spindles for ophthalmic/fine optics and flat/vehicle glass.

- Highest concentricity and rigidity for precise polishing and grinding

- Tool interface on both sides for pre- and finish-machining or according to customer requirements

- Motorized and externally driven precision spindles

- Corrosion resistant design

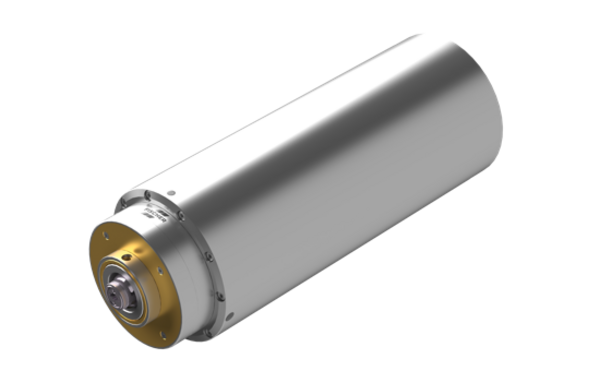

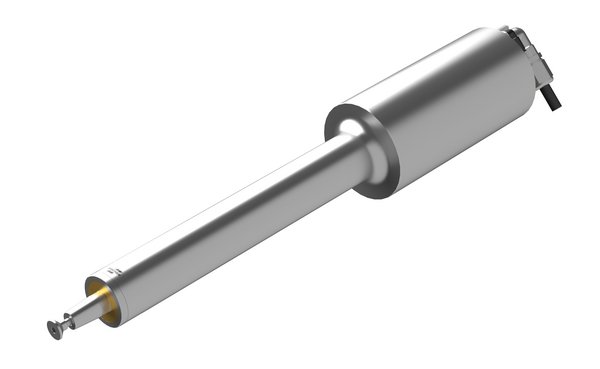

Deep hole grinding

Customized spindles with diameter/length ratio up to 1:20.

- Precision grinding spindles for belt drive or with motor and external taper for internal grinding of deep holes

- Cylindrical or offset spindle housings

- Diameter/length ratio up to 1:20 possible

Belt driven grinding spindles

Belt driven spindles for various grinding processes and applications with high precision requirements.

- Inner taper or outer taper for radial and axial loads

- UJ or HJN arbor mountings for highest precision and stability

- High precision spindle bearings with lifetime grease lubrication

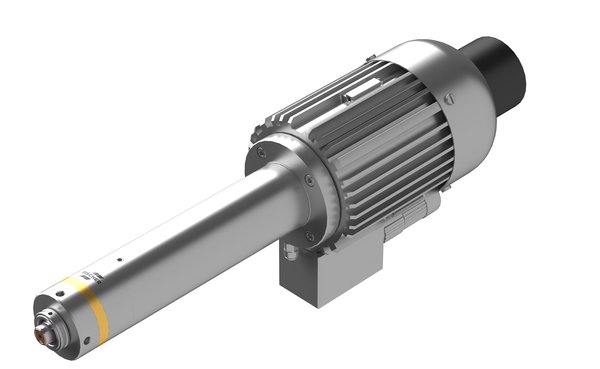

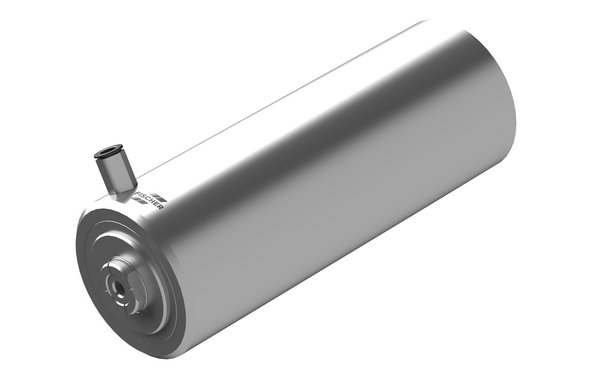

Spindles with mounted motor

High precision motorized spindles with air cooled motor.

- Available with external taper, manual HSK tool interface or integrated collet.

- Spindles with optimum running smoothness, maximum speed and highest precision