TECHNOLOGY

PERFECT ROTATION.

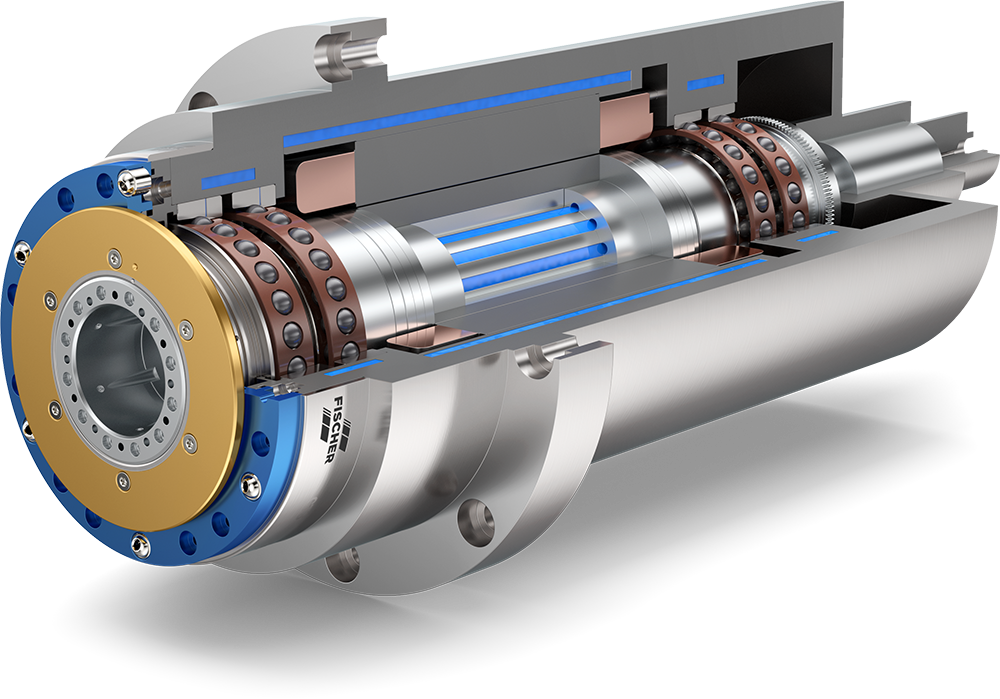

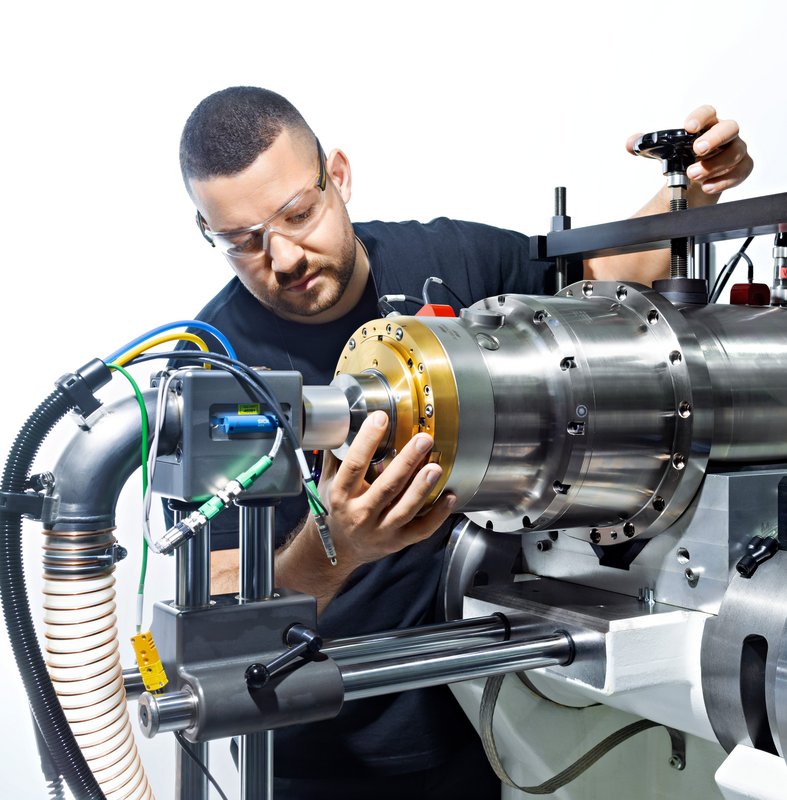

The name FISCHER stands for precise, fast and powerful rotation, and more than 85 years of experience are reflected in all our technical innovations. As an international technology leader, our expertise in development, simulation, manufacturing and performance testing stands out - market leaders from all over the world rely on FISCHER products. Whether our spindles with patented shaft cooling, compressors with specially developed air bearings or newly developed milling heads - our durable products and applications are of very high quality and designed for the best possible customer benefit.

- Cooling of all bearings, motor and shaft

- Thermal symmetry on the spindle housing

- Minimum thermal expansion of the shaft

- Efficient media routing

- More about shaft cooling and thermal simulation

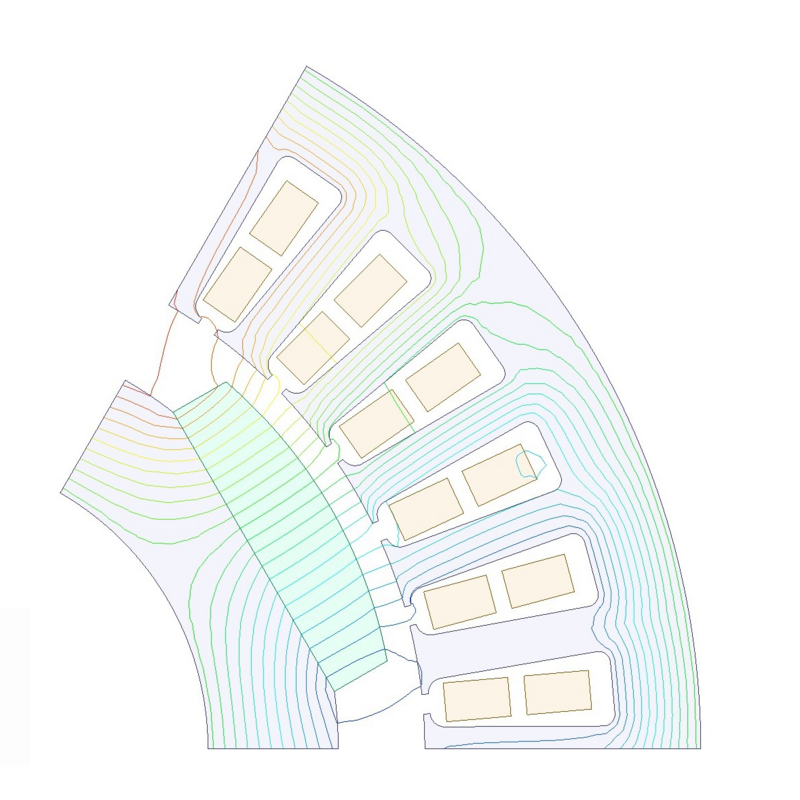

- Competence for bearing designs, service life calculations and analyses

- Different bearing technologies depending on application and product

- Hybrid precision ball bearings for high radial and axial forces

- Hydrostatic bearings for high stiffness and damping

- Air bearings for highest speeds

- More about condition analysis and condition monitoring of rolling bearings

- Competence for design and development of various drive concepts

- Optimized efficiencies

- Torque up to 1000Nm

- Highest power up to 440kW

- More about Highest speeds with FISCHER motors

- Optimized customer-specific connection to machine according to customer requirements

- Machine connection with optimized cooling for additional thermal stability

- Modal analyses in the field (frequency analyses)

- FEM (Finite Element Method) and thermal image analyses as support for optimizations

- Peripheral competence (frequency conversion parameterization, motor chokes, lubrication units, etc.)

- More about milling head

- Milling and Turning in one set-up

- Holding torque at any position

- Bearing-load relief

- Media variety: KSM, MMS, dry air

- Pressures up to 180 bar

- Dry-running safe

Template

Template

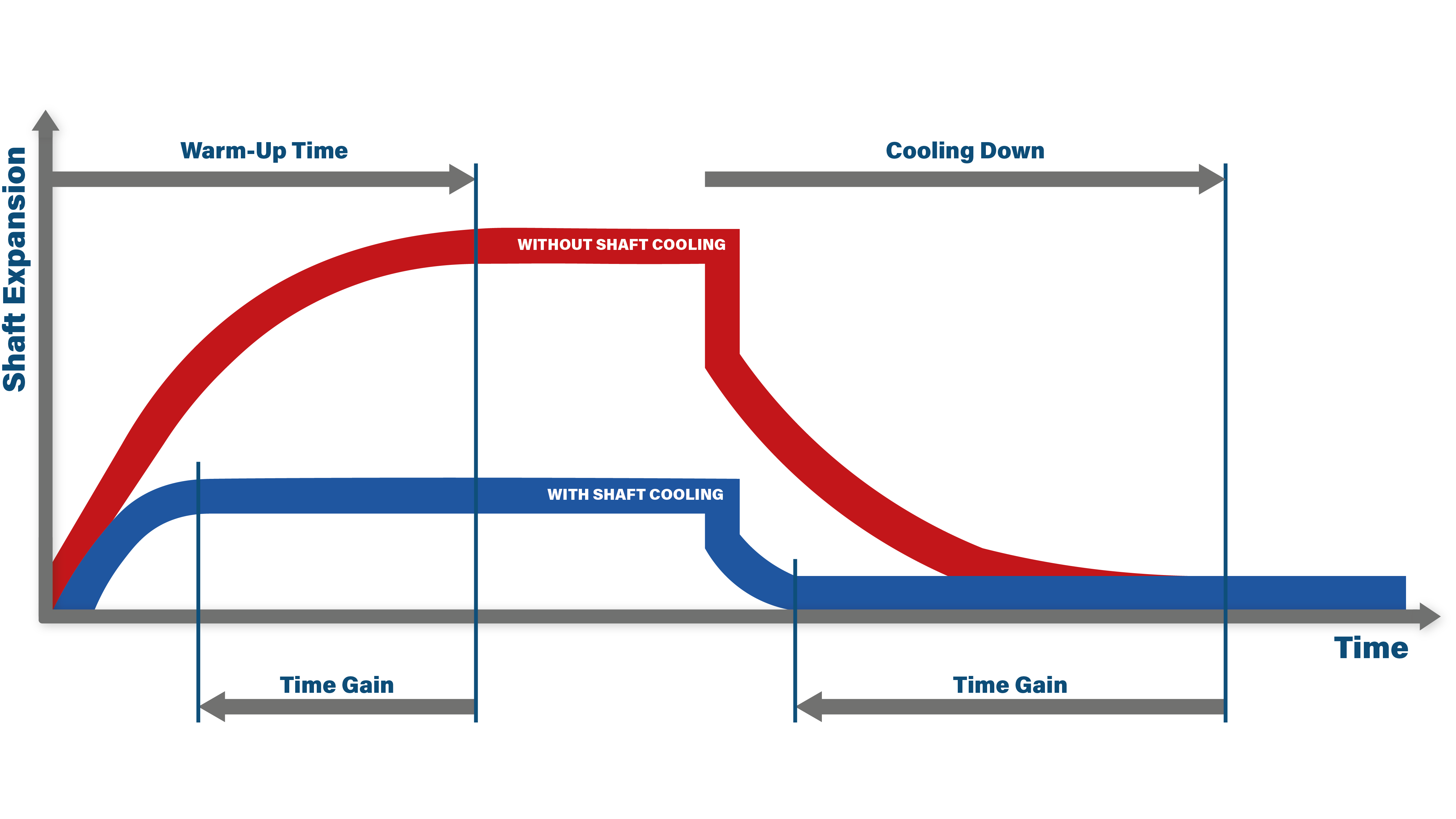

MORE TO COOLING

SHAFT COOLING AND THERMAL SIMULATION

- Temperature-controlled HSK interface and tools due to cooling circuit integrated in spindle shaft

- Up to 70% less axial tool expansion

- Faster saturation times for warm-up and cool-down and five times shorter waiting time

- Precisely repeatable machining cycles due to thermally stable process conditions

- Increased motor overload capability by dissipating heat generated in the rotor

- Lower scrap rate due to repeatable precision

BEARING TECHNOLOGY

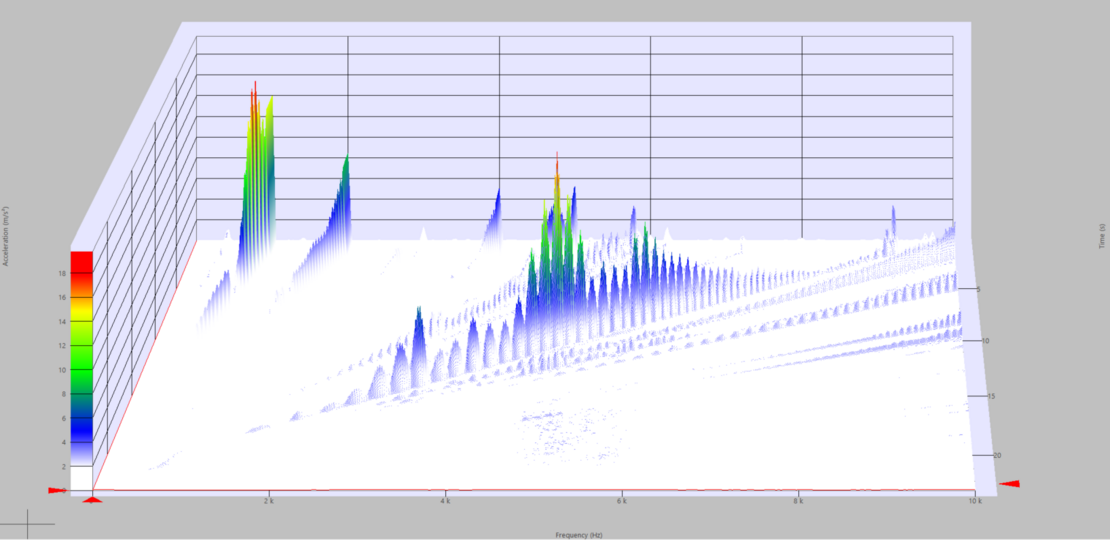

Condition Analysis and Condition Monitoring

- Bearing condition analysis on end-of-line test rigs

- Initial amplitudes of bearing frequencies (BPFO, BPFI, BSF and FTF)

- On-site cyclic bearing condition analyses on the machine

- Assessment of bearing raceways and bearing condition

- Determination of optimum machining speeds

- In coordination with customer definition of maintenance cycles

MOTOR TECHNOLOGY

HIGHEST SPEEDS WITH FISCHER MOTORS

- Expertise in the design and simulation of electric motors

- Power test benches for validation and optimization of the drive train

- Highest speeds thanks to compact and application-tailored design

METROLOGY AND DATA ANALYSIS

BALANCING

- Competence of vibration analysis

- State-of-the-art balancing software for optimal balancing results

- Use of in-house high-precision balancing tools (< G1)

- Balancing over the entire speed range or specific balancing to customer machining speeds

- Balancing up to G1 class depending on product and application

- Vibration reduction and optimization of spindles in use

SPINDLE INTEGRATION

MILLING HEAD

- Coordinated and vibration-damping spindle-milling head system

- High rigidity with very compact dimensions

- Compact rotary and swivel axes with robust bearings

- YRT axial-radial bearings for the C-axis

- Cross roller bearings for the A-axis

- Powerful drives in rotary and swivel axes for highest accelerations

- Double drive of the A-axis with up to 688Nm

- High-torque axis clamps for absolute stability

- Patented double clamping of the A-axis with up to 4'000Nm

- Precision bearings and direct optical measuring systems for maximum accuracy